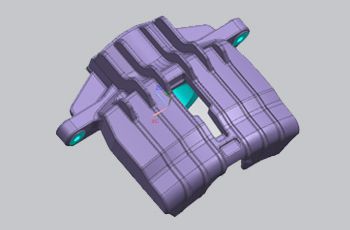

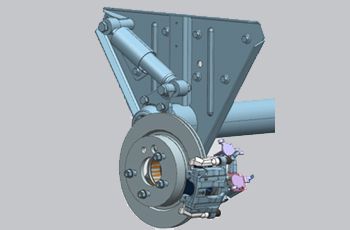

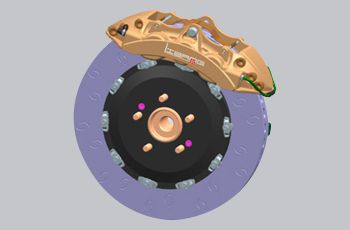

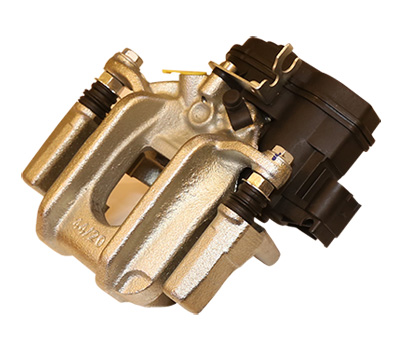

LBN specializes in delivering complete solutions to cater to all your braking system needs as well as offering comprehensive services from designing, engineering to manufacturing. Our manufacturing plant comes fully equipped with a complete range of equipment and incorporates a combination of highly experienced engineers and seasoned manufacturing professionals to enable us to provide high quality OEM brake parts and excellent service.

Our team of outstanding professionals is the core force in designing and developing the vehicle braking system, including our Japanese chief engineer who has over 40 years of experience in automotive brake field, our Japanese director who has 20 years of experience in plant on-site management, as well as 20 engineers with more than 10 years of experience and 10 managers with 15 years of experience in management of braking system production. Based on their knowledge and professional expertise in the field, we are committed to continually develop and produce cutting edge braking system to meet all our customer’s requirements.

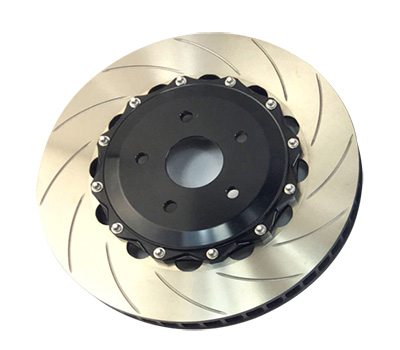

Utilizing aluminum alloy as the main raw material of our vehicle brake parts, we pay special attention to the controlling of aluminum alloy material quality through the strict control procedure of the incoming materials, aiming at guaranteeing the quality of our brake parts from the source.

A356.2 / AlSi7MG Aluminum Alloy

This series aluminum alloy is characterized by excellent casting properties, good fluidity, low linear shrinkage, high corrosion resistance, low hot cracking tendency and good air tightness. Heat treatment can be implemented for strengthening. The aluminum alloy is suitable for manufacturing brake caliper and steering knuckle.

Manufacturing process: Gravity casting

ACD12/ADC6 Aluminum Alloy

This series aluminum alloy is suitable for manufacturing motorcycle handlebar and bike pump body.

Manufacturing process: high-pressure die casting

LBN invested 7 million RMB to build complete production lines, which enables us to accomplish production processes of molten aluminum treatment, casting, machining, surface treatment, etc.

Casting Workshop

Fully automatic molten aluminum treatment equipment, automatic tilting gravity casting machine, molten aluminum holding furnace, low pressure casting machine, high pressure casting machine, mechanical sawing machine, sand core making machine and heat treatment furnace, are capable of satisfying customers' requirements on physical performance of the braking system.

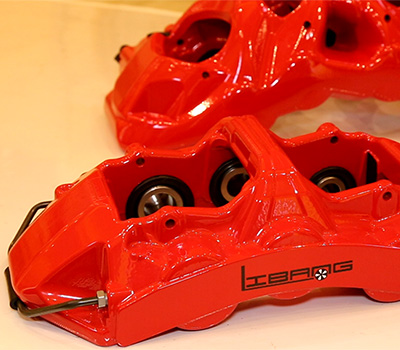

Machining Workshop

Mazak CNC machine tools are adopted for precision machining of core parts of the braking system.

Surface Treatment

Assembling Workshop

This workshop is capable of accomplishing braking system assembling and various tests for the braking system.

Utilizing aluminum alloy as the main raw material of our vehicle brake parts, we pay special attention to the controlling of aluminum alloy material quality through the strict control procedure of the incoming materials, aiming at guaranteeing the quality of our brake parts from the source.

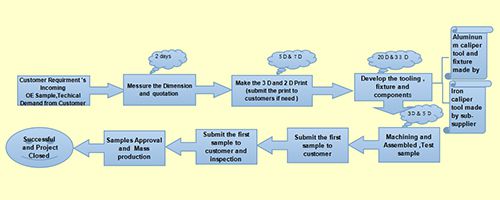

- Required OE sample and technical demands from customer

- Measure the dimension and provide quotation (2 days)

- Make the 3D and 2D print (submit the print to customers if need) (5-7days)

- Develop the tooling, fixture and components (20-33 days)

- Aluminum caliper tool and fixture made

- Iron caliper tool made by sub-supplier

- Machining and assembling, sample testing (3-5 days)

- Submit the first sample to customer for inspection

- Sample approval and mass production

- Successful and project done

With over two decades of combined experience and constant growth in the field of braking system, LBN has been providing high quality products and excellent service to a number of domestic and foreign automakers and vehicles companies. Our outstanding designing and manufacturing capabilities are particularly appreciated by our customers worldwide.